Reduce emissions & increase profit

Alternative fuels

in the cement industry

Waste derived fuels are becoming the norm in the cement industry. Fossil fuels become the "alternative" fuel as many kilns are able to substitute over 50% of their fossil fuels.

Our goal is to achieve 100% alternative fuels. Our high quality alternative fuel portfolio, combined with our extensive knowledge on the cement kiln process, we make this goal a reality. Join other cement plants in setting a new standard for the industry.

Trusted in the cement market over three decades

N+P Group was one of the first to produce and supply waste derived alternative fuels to the cement industry. Since our founding in 1992 we have continuously developed our fuel portfolio and we are proud of our position as market leader and pioneer for the cement industry. We are bringing innovative concepts, but also continue to supply various grades of RDF and SRF to the cement market.

Sustainbililty within the cement industry

The use of waste-derived alternative fuels is a key sustainability practice in the cement industry. It can help to reduce greenhouse gas emissions, conserve natural resources, and provide a more sustainable solution for waste management. However, it is important to ensure that high-quality alternative fuels are used safely and effectively to ensure benefits.

The use of Alternative Fuels in Cement Production

Misconceptions of engineers about replacing fossil for alternative fuels within your production process.

Claim your free copy

N+P Group as one of

Europe’s market leaders

For the development, production and supply of waste derived alternative fuels. We take pride in the fact that we have developed bespoke fuel solutions for many different kiln systems in the world. Our portfolio covers RDF type of materials up to pulverized solutions to achieve 100% TSR and anything in between. Learn from our experience.

Together we maximize substitution rates

The cement industry is a significant contributor to global carbon emissions, with cement production accounting for around 7% of global CO2 emissions. The industry has a significant environmental impact, including the consumption of natural resources and the generation of waste. However, there are various sustainable practices that cement producers can adopt to reduce their environmental impact and improve their sustainability.

Decarbonising cement production

Alternative fuels help reduce the carbon footprint of cement plants.

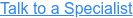

Alternative Fuel: Subcoal®

Subcoal® pellets are a high quality fuel substituting up to 100% of coal.

Why AF works for cement producers

AF can be used in existing (multi-) burner systems to substitute fossil fuels.

The right quality for cement production

We know that poor quality has a dramatic effect on your emissions, product quality, throughput, TSR rates or even loss of production hours.

Based on our vast database and knowledge within the cement industry, we help you achieve the highest replacement rates possible within your existing process.

Waste legislation:

what about the paper work?

To move and handle waste, you need to meet regulations under the EVOA EG 1013/2006. N+P Group has made over 4.000 notifications to over 26 countries worldwide. With this experience, the experts at our legislation department can advise you to make sure everything is carried out with the right documentation and permit applications.

From our production plant to your cement factory

To secure a constant supply of alternative fuels to your cement plan a strong logistics partner is essential. N+P Group does not only produce, but also takes care of the delivery of the alternative fuels to your production location with our logistic routes all across the world using various modalities, from trucks to vessels, trains or sea containers.

R&D - Waste pioneers in the cement market

Understanding the cement production processes in detail, helps us to develop and offer bespoke solutions to maximize TSR rates. On the other hand, a deep understanding on waste compositions and treatment processes help us to create valuable materials.

Ready to talk with an expert?

Our experts are happy to help you with your question or enquiry.

We repurpose waste

into sustainable resources.